RCD testing is a legal requirement in New South Wales, but many Sydney businesses aren’t sure how often it needs to be done or what standards apply. According to SafeWork NSW and the Work Health and Safety Regulation 2017 (NSW), every workplace must have a clear system in place to check residual current devices (RCDs), also known as safety switches. These checks are designed to protect staff, customers, and property by preventing electric shock and fire hazards.

In this guide, you’ll learn what the AS/NZS 3760 and AS/NZS 3012 standards say about RCD testing requirements, how they apply to different industries such as offices, warehouses, and hospitality venues, and why working with a licensed commercial electrician in Sydney is the safest way to stay compliant.

Why Every Workplace Needs RCD Protection

RCDs track small changes in current flowing through an electrical circuit. If a leak or imbalance is detected, these switches cut power quickly (often in under 30 milliseconds), potentially preventing electric shocks or fires. For a commercial property in Sydney, each RCD can be critical to workplace safety.

- RCDs detect faults faster than older circuit breakers.

- They are especially important in areas where moisture, heavy machinery, or frequent equipment use might raise the risk of electrical exposure.

- According to Australian safety guidelines, RCDs reduce the chance of severe electric shock by cutting off power promptly.

Two Main RCD Types

In commercial environments, most RCDs fall into two main categories: portable and fixed. Each type has its own use cases and compliance considerations.

1. Portable RCDs

- Often used for temporary work sites or outdoor events.

- Plugged into sockets to protect a single device or extension cord.

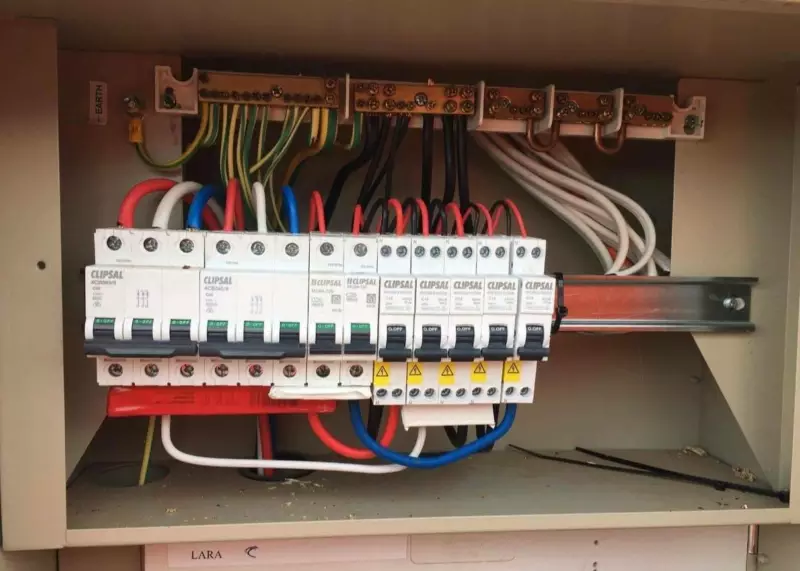

2. Fixed RCDs

- Installed in your switchboard.

- Monitors entire circuits that feed multiple outlets in a workspace.

Without functional RCDs, your building could face higher liability, especially if an electrical accident occurs. That’s why the state emphasizes routine checks.

Know Your Testing Obligations

In New South Wales, RCD testing is not optional. Under the Work Health and Safety Regulation 2017 (NSW), business owners, building managers, and anyone in control of a workplace (known as a “duty holder”) must ensure all electrical equipment is safe to use. That includes regularly testing and maintaining residual current devices (RCDs).

According to SafeWork NSW and standards such as AS/NZS 3760 and AS/NZS 3012, two types of checks are required:

- Push-button test – confirms the RCD physically trips (usually carried out monthly for fixed RCDs, or every 3 months for portable RCDs).

- Trip time test – measures how quickly the RCD cuts power under fault conditions (recommended every 6–12 months, depending on the workplace environment).

Failing to carry out these checks can expose businesses to legal penalties, insurance issues, and serious safety risks.

In many cases, SafeWork NSW recommends documenting results so you can prove compliance if audits or inspections occur. For typical commercial buildings, the industry practice might be:

- Monthly push-button tests for fixed RCDs

- Annual or biannual trip tests performed by a qualified electrician

RCD Testing vs. Test & Tag: What’s the Difference?

It’s common for businesses to confuse RCD testing with test and tag, but they cover different aspects of electrical safety:

- RCD Testing – verifies that the safety switch in your switchboard or portable unit will trip fast enough to prevent electric shock.

- Test and Tag – ensures appliances, tools, and extension leads are safe to use and clearly marked with inspection tags.

Both are required under NSW law and work together to reduce electrical hazards. For example, in a warehouse, RCD testing ensures the circuit protection works correctly, while test and tag makes sure the forklifts’ charging leads and portable tools are safe.

If you’re ever uncertain about the specifics, ask a licensed commercial electrician for confirmation. They can walk you through your building’s unique requirements and check that each device meets the correct standards.

Follow a Clear Testing Schedule

Setting up a structured testing routine is the easiest way to stay compliant and reduce risk. A clear schedule ensures RCD checks aren’t forgotten, especially in busy workplaces where safety can easily be overlooked.

Below is a sample testing schedule based on SafeWork NSW guidance and AS/NZS 3760 recommendations:

| RCD Type | Push-Button Test | Trip Time Test | Recommended Tester |

| Portable RCD | Every 3 months | Every 12 months | In-house trained person |

| Fixed RCD | Monthly | Every 6-12 months | Licensed electrician |

Why These Intervals Matter

- Push-button test: Checking that the RCD can physically trip is crucial, because a stuck device offers no real protection.

- Trip time test: This measures how quickly the RCD cuts power—including a proper reading to confirm you’re within safe limits.

Each check ensures the device is still sensitive to current leaks and can respond at the speed it was designed for. In a busy commercial environment, small issues such as dust build-up or loose connections can affect performance. Frequent testing helps you identify and correct these problems early.

Tips to Stay on Top of Testing

- Schedule push-button tests with regular housekeeping tasks, like once a month alongside your safety inspections.

- Set recurring calendar reminders, and make sure multiple people on your team are aware.

- Keep a simple log on-site, noting test dates, results, and follow-up actions.

This approach not only helps you avoid compliance gaps but also reduces the risk of unseen malfunctions.

Document and Prepare for Audits

Keeping accurate records is just as important as doing the RCD tests themselves. Under the Work Health and Safety Regulation 2017 (NSW), businesses must be able to demonstrate that electrical safety obligations are being met. When SafeWork NSW inspectors or insurance providers request proof, detailed documentation can make the difference between a smooth audit and a costly penalty.

Every RCD test should be logged with:

- Date and time of test.

- Name of the person or electrician conducting the test.

- Type of test (push-button or trip time).

- Results or readings (e.g., pass/fail or measured trip time).

- Any corrective action taken (like replacing or repairing a faulty unit).

If a problem pops up, schedule repairs immediately. An RCD that doesn’t pass a test is a liability. Swift action not only keeps you safe but also shows due diligence if you’re ever questioned.

Plan for Future Upgrades

RCD testing is not only about compliance. It is also an opportunity to check whether your safety switches are suitable for today’s electrical demands.

Many Sydney businesses are modernising their systems to support solar panels, EV chargers, high-load machinery, or office expansions. Older RCDs may not meet current safety standards under AS/NZS 3760 and can lack the sensitivity needed for newer installations.

Benefits of Upgrading RCDs

- Faster trip times for better protection.

- Improved reliability in heavy-use or harsh environments.

- Smaller switchboard footprint, leaving space for new circuits.

- Compatibility with modern systems such as solar and smart energy monitoring.

When to Consider an Upgrade

- During an office or retail fitout when adding new lighting or data cabling.

- While upgrading a warehouse or industrial site with new machinery.

- When installing renewable energy solutions like solar or battery storage.

- If your current RCDs fail repeated tests or no longer meet compliance.

Planning RCD upgrades at the same time as other electrical work reduces downtime and saves costs. A licensed commercial electrician can check your switchboard, recommend compliant replacements, and ensure installations meet both safety standards and your business needs.

If a device fails unexpectedly, an emergency electrician can restore operations quickly and keep your site safe.

Frequently Asked Questions

1. How often should RCDs be tested in NSW?

In NSW, fixed RCDs should have a push-button test every month and a trip time test every 6–12 months. Portable RCDs should be push-button tested every 3 months and trip time tested every 12 months.

2. Is RCD testing a legal requirement in NSW?

Yes. Under the Work Health and Safety Regulation 2017 (NSW), duty holders must ensure electrical equipment, including RCDs, is regularly tested to maintain compliance and workplace safety.

3. What is the difference between RCD testing and test and tag?

RCD testing checks that safety switches trip quickly to prevent electric shock, while test and tag checks that appliances, tools, and extension leads are safe to use and clearly marked with inspection tags. Both are required in NSW workplaces.

4. Who can carry out RCD testing in NSW?

Routine push-button tests can be done by trained staff, but trip time testing must be completed by a licensed electrician to meet compliance standards.

5. What happens if RCD testing is not done?

Failure to complete RCD testing can result in legal penalties, failed audits, higher insurance risks, and increased chances of electric shock or fire incidents in the workplace.

Stay Compliant with RCD Testing in NSW

RCD testing requirements in NSW may seem complex at first, but with a clear schedule and proper recordkeeping, compliance becomes straightforward. Here is a quick recap for Sydney businesses:

- RCDs are essential for preventing electric shocks and fire hazards.

- NSW law makes regular testing mandatory, with intervals that vary by workplace.

- Both push-button and trip time tests need to be part of your routine.

- Accurate records help with audits and protect your business.

- Upgrading older RCDs ensures ongoing safety and prepares your site for future needs.

The next step is to set a calendar for testing, assign responsibility, and keep consistent records. If you are unsure about the exact requirements for your workplace, seek advice from a licensed commercial electrician who can confirm the right intervals and carry out the necessary checks.